36 pieces 10 inch deep well submersible water pump sets to Iraq

The cast iron submersible pump main part material as below:

1. The pump impeller, pump casing coupling part and motor casing is cast iron material.

2. The pump shaft is stainless steel material.

3. The bearing is graphite.

4. The winding is 100% copper with polyethylene insulation layer.

5. The rotor end ring is copper.

6. The stator casing is with 45# steel.

7. The stator is cold rolling silicon steel.

10 inch water submersible pump performance range:

1. Diameter: 10 inch submersible pump

2. Flow: 46m3/h-214m3/h

3. Head: 12m-430m

4. Power: 5.5kw-125kw/7hp-170hp submersible pump

5. Voltage: 380v/400v/420v/440v/460v/480v/600v/660v

6. Material: Cast iron/stainless steel 304/316/316L/duplex stainless/super duplex stainless steel/SS904L

Water submersible pump models:

| Pump Diameter | Model | Power | Flow rate | Head | Outlet Size | |

| Inch(") | QJ series | kw | hp | m3/h | m | Inch(") |

| 10" | 250QJ50-20/1 | 5.5 | 7 | 46-54 | 17-23 | 3" |

| 10" | 250QJ50-60/3 | 15 | 20 | 46-54 | 51-69 | 3" |

| 10" | 250QJ50-120/6 | 30 | 40 | 46-54 | 102-138 | 3" |

| 10" | 250QJ50-200/10 | 45 | 60 | 46-54 | 170-230 | 3" |

| 10" | 250QJ50-240/12 | 55 | 75 | 46-54 | 204-276 | 3" |

| 10" | 250QJ50-300/15 | 63 | 85 | 46-54 | 265-335 | 3" |

| 10" | 250QJ50-340/17 | 75 | 100 | 46-54 | 315-375 | 3" |

| 10" | 250QJ50-380/19 | 90 | 120 | 46-54 | 350-410 | 3" |

| 10" | 250QJ50-400/20 | 100 | 135 | 46-54 | 365-430 | 3" |

| 10" | 250QJ63-40/2 | 11 | 15 | 58-68 | 34-46 | 3" |

| 10" | 250QJ63-60/3 | 18.5 | 25 | 58-68 | 51-69 | 3" |

| 10" | 250QJ63-120/6 | 37 | 50 | 58-68 | 100-138 | 3" |

| 10" | 250QJ63-160/8 | 45 | 60 | 58-68 | 130-184 | 3" |

| 10" | 250QJ63-260/13 | 75 | 100 | 58-68 | 220-299 | 3" |

| 10" | 250QJ63-300/15 | 90 | 120 | 58-68 | 205-343 | 3" |

| 10" | 250QJ80-20/1 | 7.5 | 10 | 74-86 | 17-23 | 4" |

| 10" | 250QJ80-140/7 | 55 | 75 | 74-86 | 118-163 | 4" |

| 10" | 250QJ80-200/10 | 75 | 100 | 74-86 | 170-230 | 4" |

| 10" | 250QJ80-240/12 | 90 | 120 | 74-86 | 204-276 | 4" |

| 10" | 250QJ80-280/14 | 110 | 150 | 74-86 | 235-325 | 4" |

| 10" | 250QJ100-36/2 | 15 | 20 | 80-120 | 32-42 | 4" |

| 10" | 250QJ100-72/4 | 30 | 40 | 80-120 | 64-84 | 4" |

| 10" | 250QJ100-144/8 | 63 | 85 | 80-120 | 120-168 | 4" |

| 10" | 250QJ100-216/12 | 100 | 135 | 80-120 | 190-252 | 4" |

| 10" | 250QJ125-16/1 | 9.2 | 13 | 116-134 | 13-19 | 5" |

| 10" | 250QJ125-128/8 | 75 | 100 | 116-134 | 109-147 | 5" |

| 10" | 250QJ125-192/12 | 110 | 150 | 116-134 | 163-220 | 5" |

| 10" | 250QJ140-180/12 | 125 | 170 | 130-145 | 156-205 | 5" |

| 10" | 250QJ160-15/1 | 13 | 18 | 148-172 | 44183 | 5" |

| 10" | 250QJ160-90/6 | 63 | 85 | 148-172 | 77-103 | 5" |

| 10" | 250QJ160-105/7 | 75 | 100 | 148-172 | 90-120 | 5" |

| 10" | 250QJ160-120/8 | 90 | 120 | 148-172 | 102-138 | 5" |

| 10" | 250QJ160-135/9 | 100 | 135 | 148-172 | 115-155 | 5" |

| 10" | 250QJ160-150/10 | 110 | 150 | 186-214 | 128-170 | 5" |

Applications:

1. Ground water pumping

2. Farm irrigation system

3. Sea water, shipyard, offshore, floating dock, salt water, vessel

4. Drawing water from well/borehole

APK pump factory not only manufacture water pumps, but also manufacture match pump accessories, including pump control cabinet, frequency converter(ABB or as per request), cable, valve.

Testing: We tested each submersible water pump before delivery, such as dynamic and static balance testing, material analysis testing, casting testing, and submersible pump submerged in water for 48 hours to test leaking or not.Also we could send testing video, testing pictures, testing report.

Package: the well pump has 3 layers of packaging with 8mm special export wooden box. Shock absorption,moisture-proof package, standard export wooden case.

Shenlong (APK) pump factory mainly manufactures , drawing sea water, salt water, clean water, sewage water, hot water. Vertical or horizontal install.

ZhengzhouShenlong pump factory is a competitive reputable OEM&ODM submersible pump manufacturer

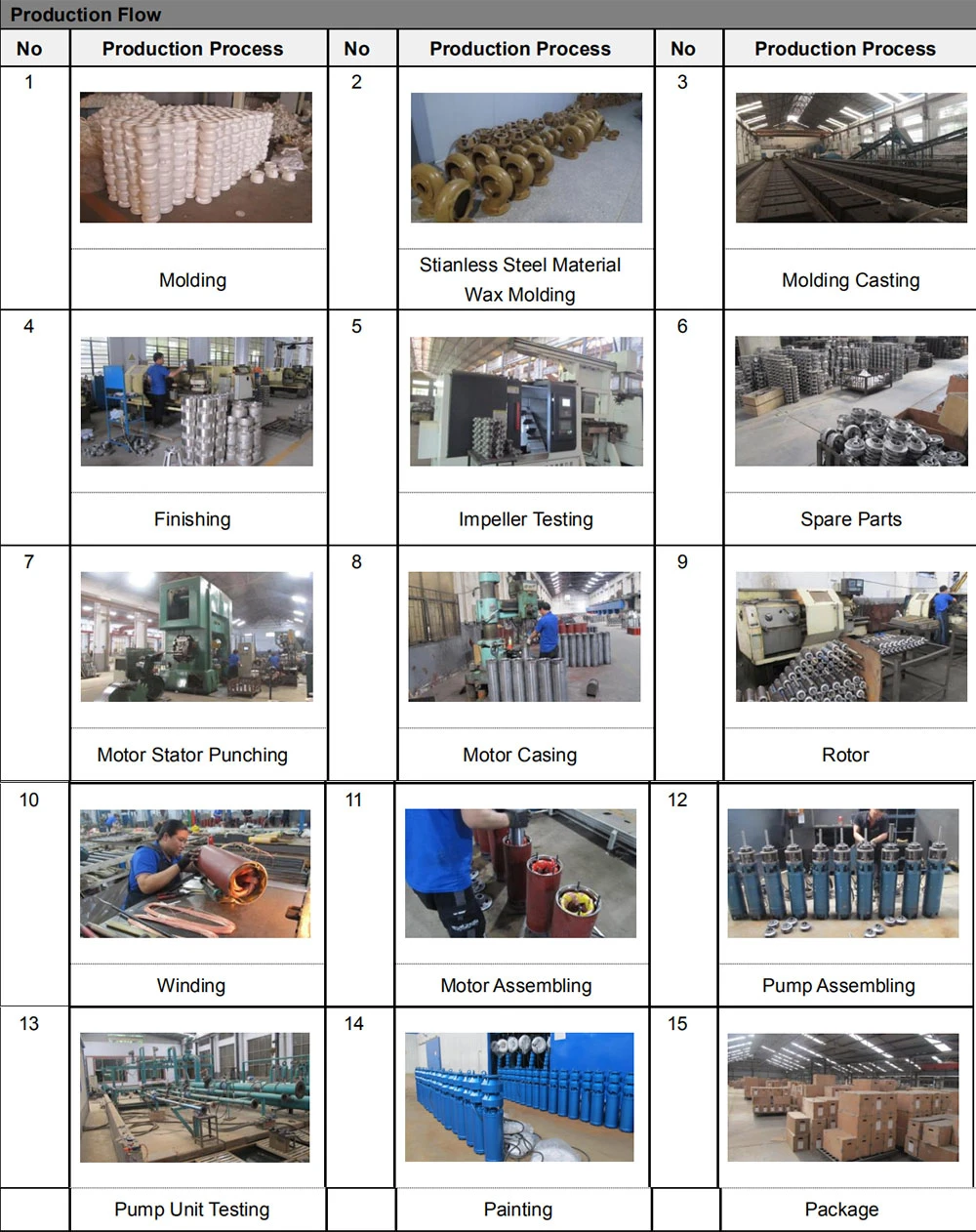

2. Fully automated pressing stamping And punching lines with ultimate levels of quality. Production and assembly departments based on German engineering. Be spoke CNC machining department utilizing 3D/2D technology and high precision tools; Professional test stations. R&D department for our continuous drive for perfection of products.

3. We have 36 sole duty quality control staffs. Among processional staffs are put in charge of Rotor dynamic balancing/Impeller static balance /Motor winding withstand voltage test /Hydrostatic pressure test of pressure bearing parts.

Certificates:

ISO;CE,BV; TUV; CCC;five stars after-sale service, or as your request, such as SGS. We are also Trade Assurance Guarantee Supplier in Alibaba and Gold Supplier in China.